Introduction

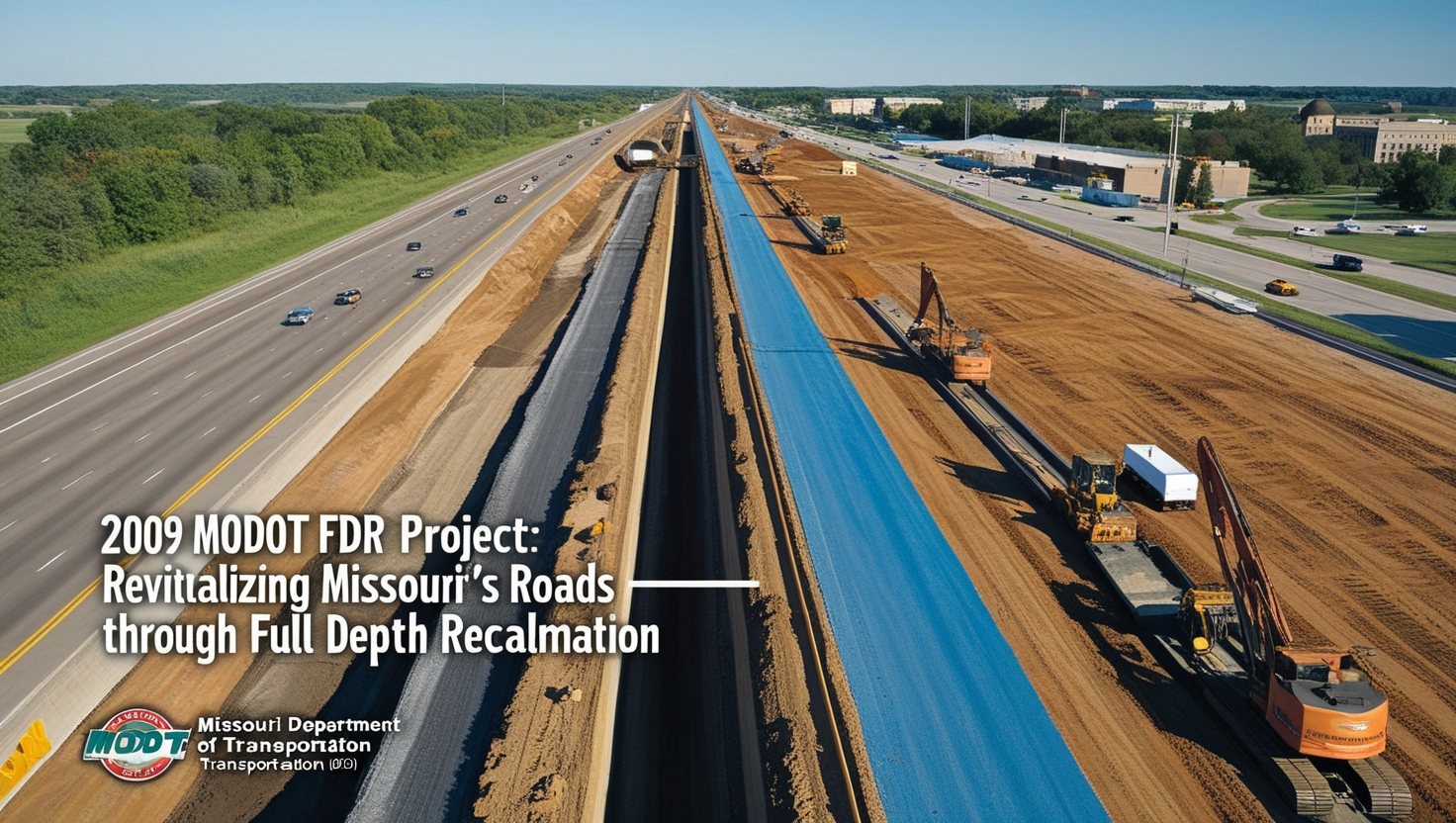

The 2009 MoDOT FDR Project was a pivotal initiative undertaken by the Missouri Department of Transportation (MoDOT) to cope with deteriorating street conditions throughout the state. This task, which focused on Full Depth Reclamation (FDR) as the number one technique, marked a widespread step closer to sustainable and green pavement rehabilitation. The 2009 MoDOT FDR Project introduced a new method of avenue preservation, proving the effectiveness of FDR in restoring structural integrity and increasing the lifespan of Missouri’s highways.

Understanding Full Depth Reclamation

Full Full-depth reclamation, often abbreviated as FDR, is a pavement rehabilitation approach that involves the reconstruction of present road layers by using recycling and stabilizing substances. In the 2009 MoDOT FDR Project, the entire flexible pavement segment was changed to pulverized and combined with a stabilizing agent. This system creates a strong and sturdy base layer upon which new asphalt or concrete can be laid. The 2009 MoDOT FDR Project established the blessings of FDR, including decreased material costs, minimized waste, and a lower environmental impact due to the recycling of current materials.

Goals and Objectives

The 2009 MoDOT FDR Project was released with numerous vital goals. The primary intention changed to extend the lifespan of deteriorating roads without incurring the excessive expenses associated with the entire reconstruction. Using FDR, MoDOT aimed to maintain Missouri’s road infrastructure fee-powerfully, decreasing the need for frequent maintenance. The venture also sought to lower the environmental effect of street construction, as FDR reduces the need for brand-new substances and minimizes transportation emissions associated with hauling debris.

In addition to those environmental and economic goals, the 2009 MoDOT FDR Project aimed to enhance road protection for Missouri drivers. By improving the structural integrity of road surfaces, FDR reduces troubles like potholes and cracking that can pose risks to motorists.

The Process of Full Depth Reclamation

The 2009 MoDOT FDR Project utilized a scientific technique to ensure the effective reclamation of Missouri’s roads. The first step involved assessing existing road conditions to decide the feasibility of FDR. The roads chosen for the assignment had excellent wear but retained enough structure to enjoy the reclamation method. After selection, the MoDOT group initiated the FDR process by pulverizing the existing asphalt layer along with a portion of the underlying base materials.

Next, a stabilizing agent was introduced to the pulverized fabric. For the 2009 MoDOT FDR Project, common stabilizers protected cement and lime, which were selected based on the characteristics of the soil and other local elements. Once stabilized, the combination was compacted to shape a stable base layer. Finally, a new layer of asphalt or concrete was carried out to finish the road rehabilitation.

Challenges Faced

Despite the blessings of Full Depth Reclamation, the 2009 MoDOT FDR Project encountered challenges throughout its execution. One of the first problems changed into adapting FDR strategies to Missouri’s variable soil sorts, which required cautious checking out and choice of stabilizers. Weather situations additionally posed challenges, as excessive temperatures should impact the effectiveness of the stabilization method. Additionally, because FDR became relatively new in Missouri at the time, MoDOT had to spend money on specialized equipment and schooling to ensure the mission’s success.

Another project, at some point during the 2009 MoDOT FDR Project, involved maintaining site visitors’ waft on lively roads while carrying out considerable pavement rehabilitation. MoDOT evolved site visitor control strategies to minimize disruptions, but street closures and detours have often been unavoidable. Despite those demanding situations, the challenge ultimately achieved its goals, proving FDR to be a feasible solution for Destiny road renovation projects in Missouri.

Environmental Impact

One of the 2009 MoDOT FDR Project’s main advantages is its high-quality environmental effect. Traditional road reconstruction techniques frequently generate huge waste by removing antique pavement substances. In assessment, FDR recycles those substances on websites, appreciably lowering the task’s ecological footprint. This technique also reduces the need for brand-new materials, maintains herbal assets, and decreases the amount of consumption associated with fabric manufacturing and transportation.

Long-Term Benefits

The 2009 MoDOT FDR Project left an enduring effect on Missouri’s avenue network. By choosing FDR, MoDOT carried out a durable, powerful solution that prolonged the life of the kingdom’s highways. The rehabilitated roads are more extraordinary proof against weathering and day-by-day wear, ensuring smoother and more secure tours for motorists. Additionally, MoDOT has saved on renovation fees over the long term by reducing the want for standard upkeep.

The fulfilment of the 2009 MoDOT FDR Project also served as a model for other states thinking about FDR for their avenue rehabilitation desires. MoDOTs demonstrated that with the right plans, trying out, and stabilization, FDR may be correctly applied to diverse road types, even people with unique challenges.

Conclusion

In conclusion, the 2009 MoDOT FDR Project became a milestone in Missouri’s approach to avenue maintenance. By using Full Depth Reclamation, MoDOT not only effectively addressed instantaneous street troubles but also set a precedent for sustainable infrastructure management. The mission proved that FDR is a possible, environmentally pleasant alternative to traditional road reconstruction strategies, extending pavement life while decreasing expenses and environmental impact.